Msd Ignition Module Wiring Diagram

I recognize that the ignition control part of an EFI system can be the most intimidating part of the entire project. And most EFI System manufacturers seem to focus more on "how to connect it" than "how it works", so even after some folks get it working they really don't know what they did. The purpose of this article is to drill down just a little into the igntion wiring for the Holley Terminator / Terminator X and Holley Sniper EFI Systems, comparing these two it a bit more detail than I've seen done elsewhere. If you can here just looking for tips on wiring the Terminator or Terminator X EFI ignition control, you can jump to that.

Sniper Ignition Wiring

The Sniper differs from the Terminator in that it has no EST/SPOUT signal--only a points output. That is why it cannot control ignition timing using the the GM Small Cap HEI or Ford TFI ignition. It can, however, be used to control the timing on a fixed-advance distributor provided that the rotor phasing is correctly advanced. Holley offers two *three methods, using either the new Holley HyperSpark Distributor, the Holley Dual-Sync Distributor or the other involving an MSD distributor with a rotor phasing kit I will discuss those and then offer one more off-the-radar solution that some may want to try. What works best for you will depend on product availability for your application as well as your budget (not to mention your ability to deal with frustration.)

Sniper Ignition Control Using Holley HyperSpark Distributor & Ignition System (Preferred!)

*Updated June 2018: WIth the recent release of the Hyperspark distributor there is NO REASON that anyone should choose any other means of ignition timing control for their Sniper EFI System. The cost and ease of installation alone make this a no-brainer.

The HyperSpark operates with the Sniper EFI System identically to the Dual-Sync distributor (mentioned below) but costs 33% less and requires no adapter harness. Like any of the Sniper ignition timing control options it requires either a coil driver module or an ignition box but the next big plus in favor of the HyperSpark distributor is the availability of the HyperSpark Ignition Box and HyperSpark Coil. When installed together these three combine to make wiring this almost too easy. Three wires must be terminated but the rest of the system is plug-and-play with Metri Pack Connectors and two ring terminals for power and ground.

As for all of the stuff below about rotating the engine to 50 degrees before TDC and this and that to get the rotor phasing correct--HyperSpark Distributor installers get a pass. If you can manage to set the engine on top dead center (the "0" mark on the harmonic balancer) on the compression stroke then the hard work is done. The kit includes a rotor phasing cap that holds the rotor precisely where is must be relative to the base of the distributor. You simply drop the distributor in place, lock it down, and install spark plug wires.

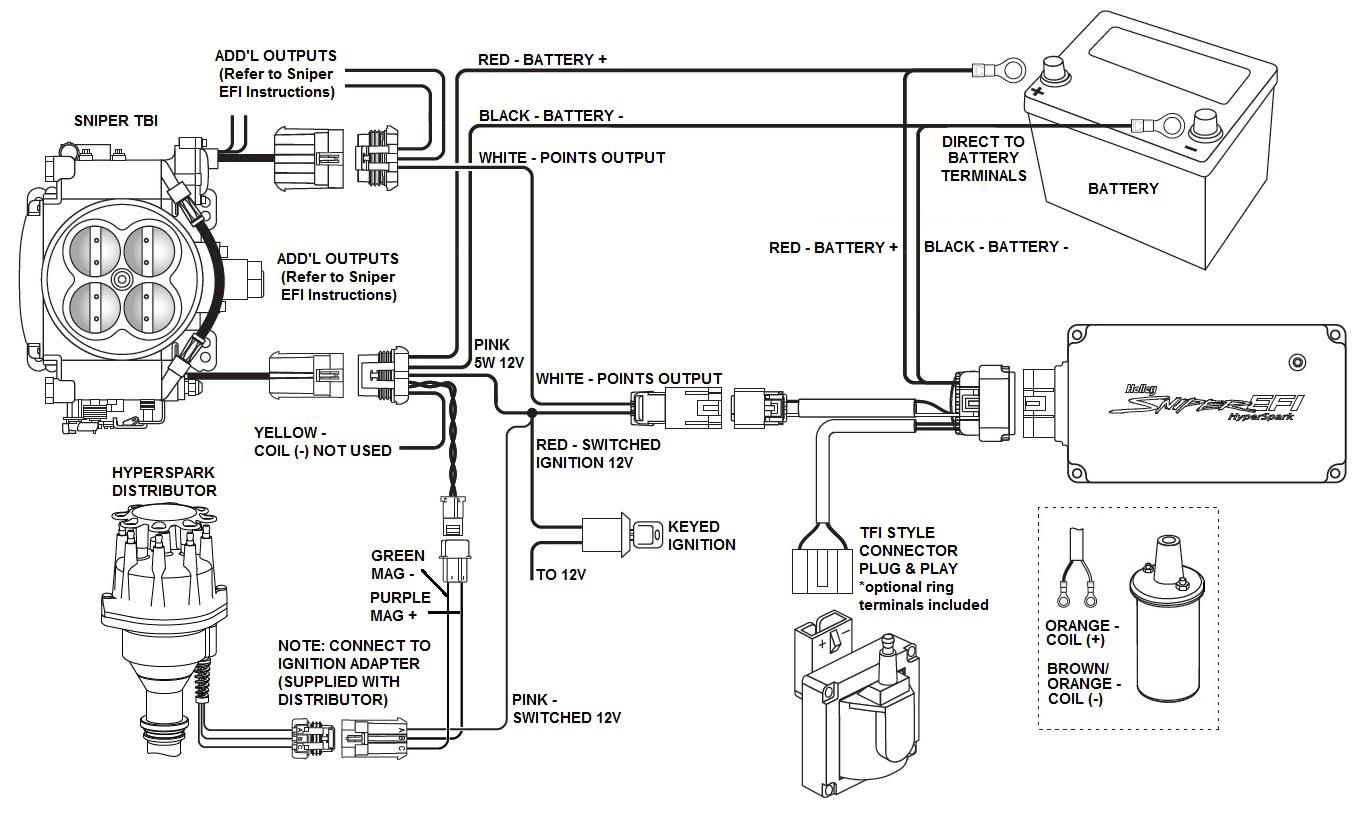

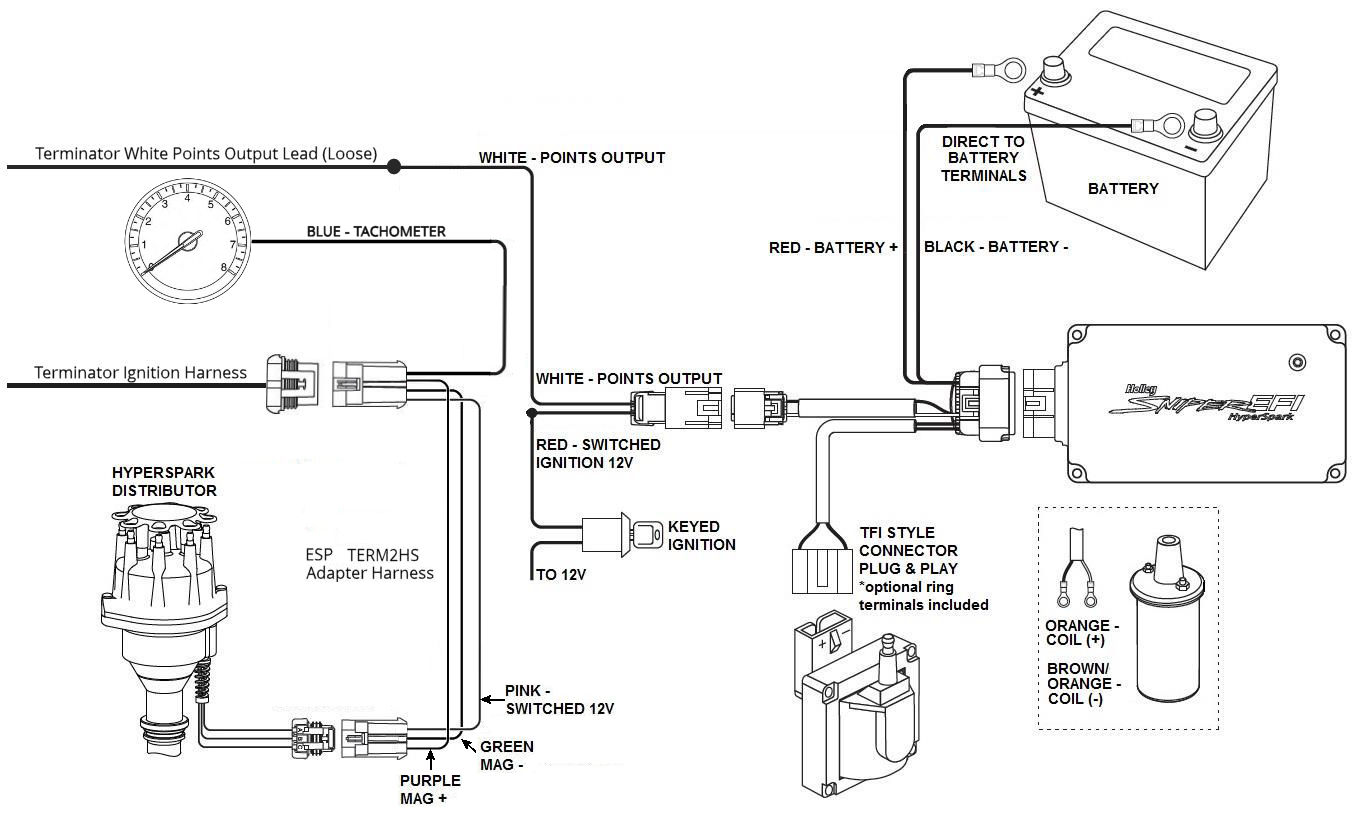

The only challenge? At this writing only one application has been announced (for the Chevrolet Small/Big Block Engine, of course.) But I fully expect Holly to release a robust line of different applications before they call their work in this area complete. Here is a wiring diagram showing the installation of the complete HyperSpark ignition including the distributor and optinoally-available ignition box and coil:

Sniper Ignition Wiring with Holley Hyperspark Distributor and Ignition

Note that the your Sniper EFI System must be running Handheld firmware 1.1.7 or higher, ECU firmware 1.1.1 or higher to operate with the HyperSpark ignition. If you use the Sniper EFI Software to configure your HyperSpark ignition you must use version 1.1 Build 2 or higher. Once installed as shown above, the Sniper EFI System should be configured as follows, This is done either using the setup wizard (if doing a new installation) or using the handheld tuning capabilities (navigate to Tuning > Advanced > Adv. Ignition for the Output Dwell and Tuning > System > Ignition Setup for the other three.)

- Ignition Type: HyperSpark

- Reference Angle: 57.5

- Inductive Delay: 100.0 usec

- Output Dwell: 2.0 msec

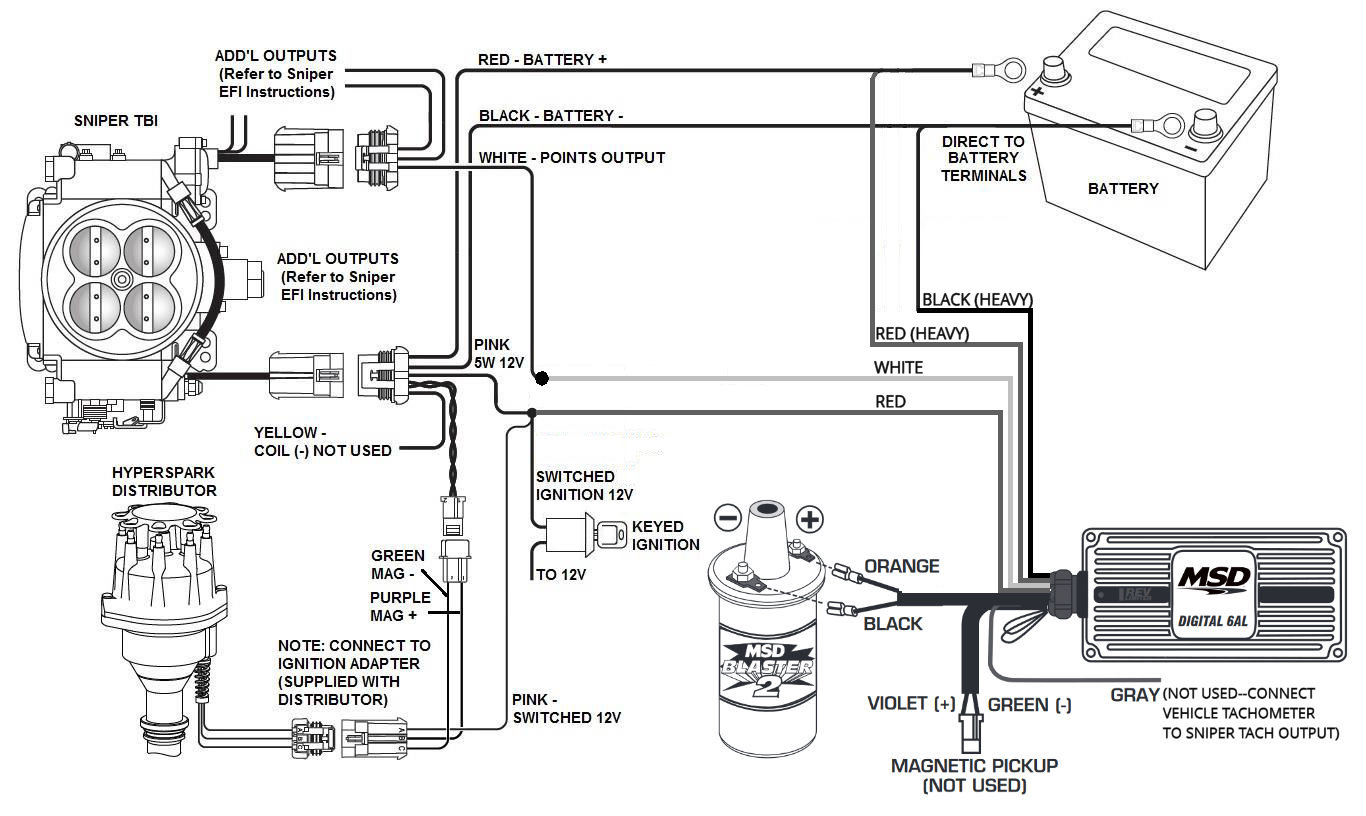

It's not mandatoryto use the HyperSpark ignition and coil with your HyperSpark distributor. You can use any standard external coil and ignition box (or the Coil Driver Module included in the Sniper 4150 EFI System.) Configuration is identical to that shown in the previous paragraph. Below is an example of the wiring for an MSD 6AL. Other capacitive ignition boxes will be wired similarly.

Sniper Ignition Wiring with Holley Hyperspark Distributor and MSD Box

Sniper Ignition Control Using Holley Dual-Sync Distributor

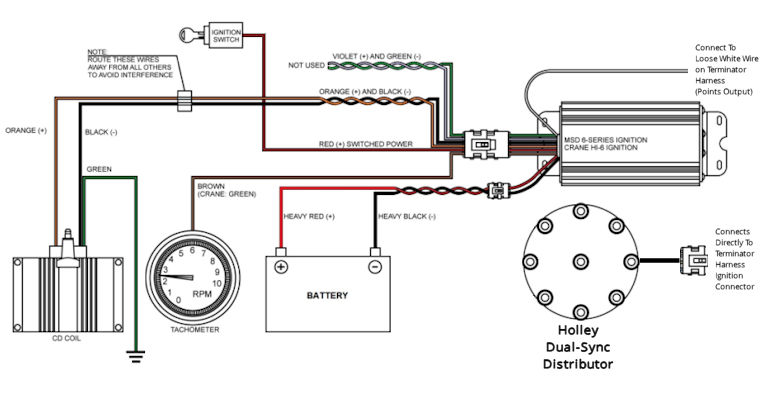

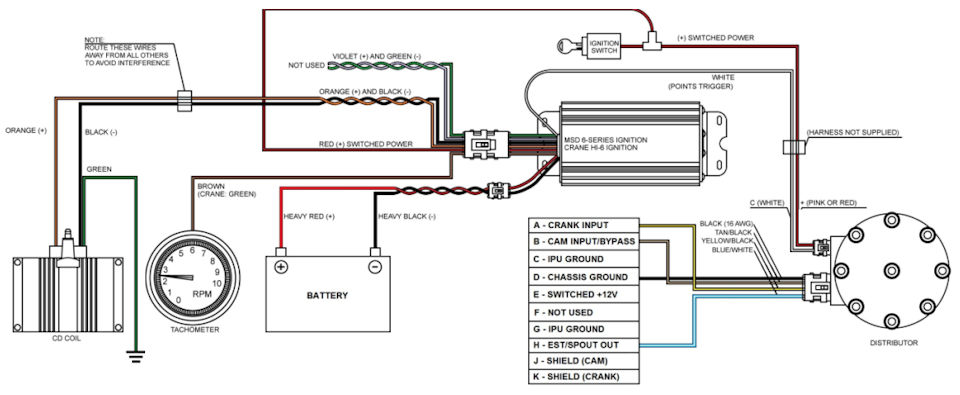

If no HyperSpark Distributor is available for your application then I recommend performing Sniper timing control with the Holley Dual Sync Distributor. No lock-out procedure or rotor phasing kit is necessary and the installation is greatly simplified via a adapter cable that connects the Holley EFI distributor's 10-pin connector to the Sniper 2-pin crank signal connector. Just like when using an MSD distributor with the Sniper, the included coil driver module or a CD box must be used. These two images show each without and with a CD box:

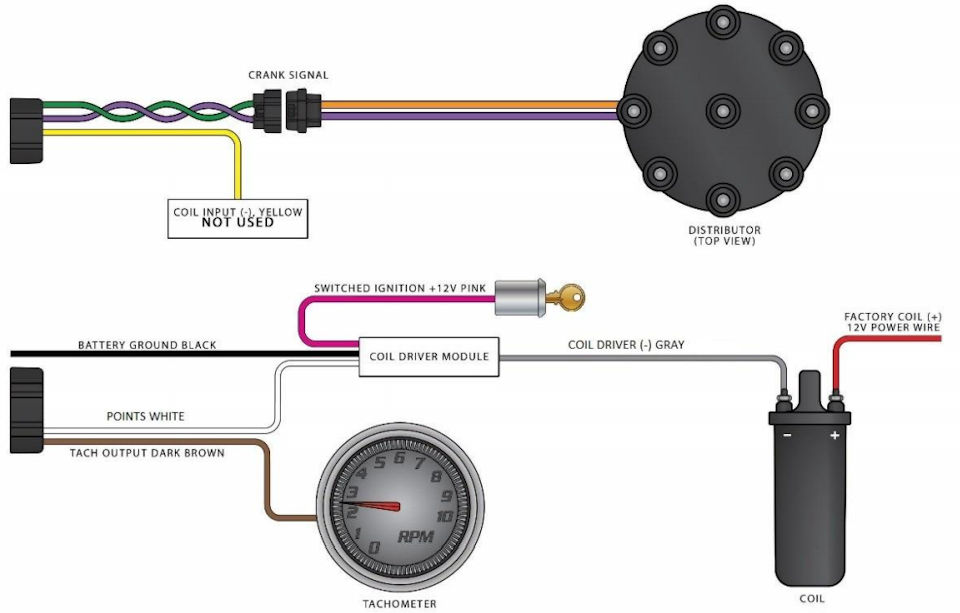

Sniper Ignition Wiring with Holley Distributor, without CD Box

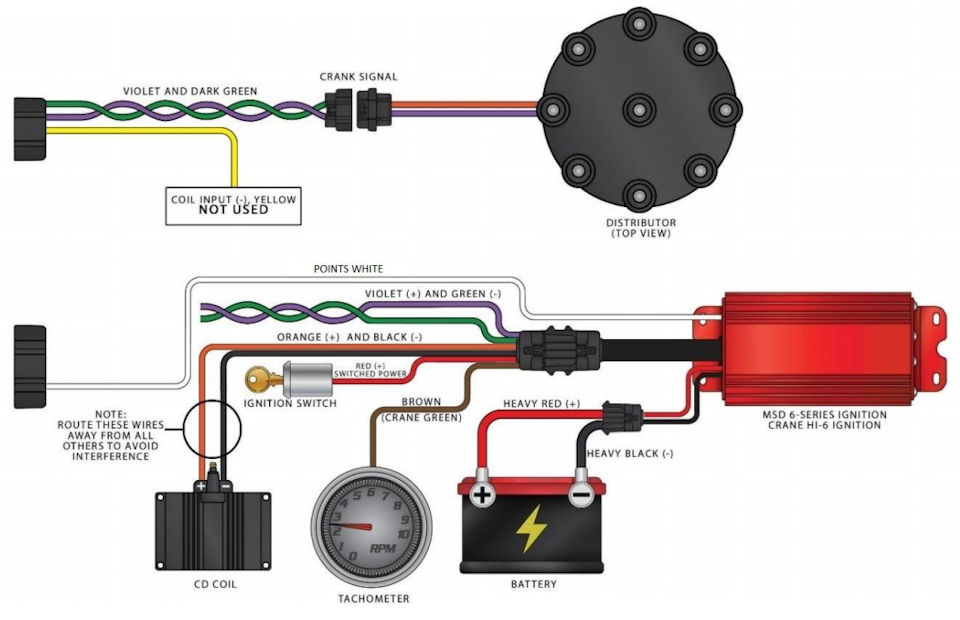

Sniper Ignition Wiring with Holley Distributor, with CD Box (MSD 6A Shown)

Here's a great video detailing the setup of the Holley Dual-Sync Distributor with the Shiper EFI System. If you follow these instructions you can set the ignition configuration as follows:

- Ignition Type: Holley Dual Sync

- Reference Angle: 50.0

- Inductive Delay: 100.0 usec

- Output Dwell: 2.0 msec

Sniper Ignition Control Using MSD Distributor

I do not recommend Sniper ignition control using the MSD distributor if a Holley HyperSpark or Dual-Sync Distributor is available for your application. I highly recommend using the Holley dual-sync distributor instead. Yes, I know that many of you come into this relationship already having an suitable MSD distributor. I encourage you to carefully consider the costs.

Some customers are struggling with RFI problems that seem to be introduced by the magnetic pickup. This has nothing to do with MSD--it's just the nature of a magnetic pickup in a high-RFI environment. It works flawlessly triggering a battle-hardened ignition system but when connected to more sensitive electronics it leaves the potential for issues. The Holley DSD, on the other hand, uses a hall effect pickup which simply doesn't struggle with the same issues as a magnetic pickup. Plus the Holley DSD is much easier to set up in the first place.

That stated, an MSD distributor can be used to perform ECU-controlled timing with the Sniper ECU. Both mechanical and vacuum advance must be locked out and a rotor phasing kit must be installed and adjusted accurately. With the advance locked out, the rotor phasing kit allows you to manually set the position of the rotor to the correct location. This can be done with or without a capacitive discharge box. Just like when using the points output with the Terminator, a coil driver module must be used between the ECU Points output and the COIL (-) if a CD box is not used.

If you choose the MSD distributor route for doing Sniper ECU-controlled, timing, I do have some suggestions. Using the Sniper software, you can go to System Parameters > Engine Parameters and find the Ignition section. The ignition type should be correctly set to "Magnetic" but the Minimum System Voltage will be 0.00v and the Filtering will be Low. You will need to tune these values. Some have found that 0.65v is a more appropriate MSV, and some also prefer to increase the filtering on this to "High". Note that if you increase the MSV too high then it will have trouble detecting any signal when cranking.

If the above suggestions do not eliminiate the RF interference problem, another user I know went back to the original non-adjustable rotor. It sort of defies logic why this works but he claims it did the trick for him and I'm sure he's right. Be aware that this makes an already somewhat arduous process of setting the timing even more of a challenge as you have to now use the distributor position to compensate for spark angle at maximum torque. I would absolutely consider this a last resort and only consider it if the paragraph above does not solve the problem.

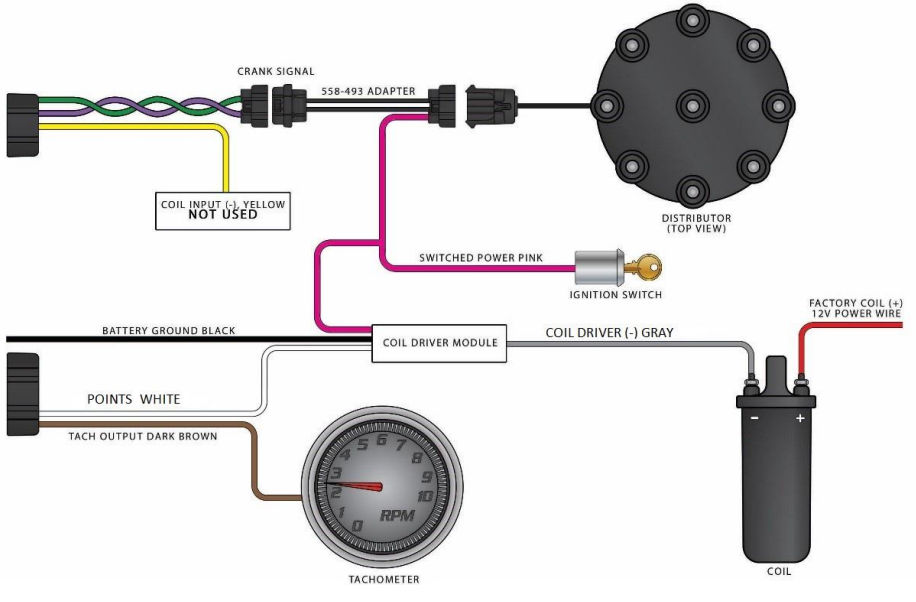

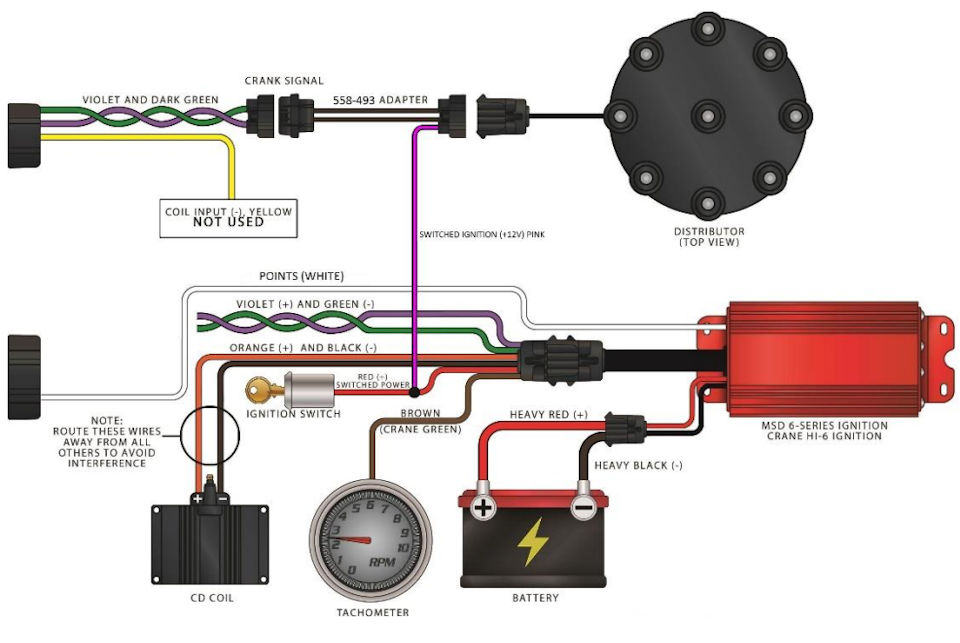

These next two wiring diagrams show how to conduct ECU timing control with an MSD distributor both with and without a CD Box:

Sniper Ignition Wiring with MSD Distributor, without CD Box

Sniper Ignition Wiring with MSD Distributor, With CD Box (MSD 6A Shown)

Watch this video for detailed instructions on how to setup an MSD Pro-Billet Distributor for use with the Sniper EFI System. If you follow these instructions then you will want to set your ignition settings as follows:

- Ignition Type: Magnetic

- Reference Angle: 45.0

- Inductive Delay: 60.0 usec

- Output Dwell: 2.0 msec

Sniper Ignition Control Using GM Large Cap HEI Distributor (Updated!)

There is one other method that has worked for some folks. That is to use a GM Large Cap HEI distributor. Compared to the first two methods this requires significantly more engineering, so proceed completely as your own risk. We know this does work, and it can save you a few hundred bucks, but I still believe that the large majority of folks out there are better served to use the Holley Dual-Sync Distributor.

This method requires that you get a GM Large Cap HEI distributor with the 4-pin module in it. GM offered these wtih 4-, 5-, and 7-pin modules. It is entirely likely that the 5- and 7- pin versions can be used as well but that is beyond the scope of this article. The 4-pin module has connectors labled B, C, W, and G. Attach them as follows:

- Pin B: Leave Disconnected. This is the power for the module. You're not actually using the module, you are just picking up the signals you need at these points.

- Pin C: Connect to the gray wire on the coil driver included with your Sniper EFI System.

- Pin W: Connect to the purple wire (Crank +) on the 7-pin connector

- Pin G: Connect to the green wire (Crank -) on the 7-pin connector

I have heard that sometimes it is necessary to reverse the purple and green wires on some distributors. Also, as implied above, you need to use the coil driver module. Connect the other wires as shown in the previous examples.

In addition to this, you need to lock out the mechanical and vacuum advance (as is done in the MSD method, above.) Rather than use some sort of rotor phasing kit, you just set the rotor phasing when you lock out the vacuum advance. As I said, this is a bit of a hack so that's part of the adventure.

Update: Recently, Ian of TurboCamaro.CA created this AMAZING VIDEO of his success setting up the GM Large Cap HEI distributor to do Sniper EFI System ignition control. This is a 30-minute video that is FULL of details. It is on a 6-cylinder version of the large cap HEI but it should work as well for the 8-cylinder version.

NOTE: If you are struggling with making any of the ignition timing control methods above work, check out this handy ignition testing technique for point-output controlled systems.

Terminator / Terminator X Ignition Wiring

Unlike the Sniper EFI System, the Terminator (HP / Dominator) and Terminator X ECU provides two ways to do ECU-controlled ignition timing: Points Output (identical to the Sniper) as well as electronic spark timing /spark output timing (EST/SPOUT) signal. It should not be surprising that wiring the Terminator EFI Systems to control ignition timing using the Points Output signat is very similar to doing so on the Sniper. Like with the Sniper, the white Points Output wire is used to ground the coil through either the Holley Coil Driver Module (PN 556-150) or a capacitive ignition box (like the HyperSpark or MSD 6EFI) and distributed using the Holley HyperSpark Disstributor or Holley Dual-Sync Distributor.

Terminator Ignition Control Using Holley HyperSpark Distributor & Ignition System

Personally, I am a huge fan of the newly released HyperSpark ignition system. Nothing beats it for plug-and-play simplicity. We offer a harness (PN ESP TERM2HS) that reduces the number of manual terminations to only one--LESS required by the Sniper! The HyperSpark ignition box does not offer a dedicated tach output signal but the Term2HS harness provides a tach output signal (blue wire.) You can use that to drive the tachometer. Some factory OEM tachometers may additionally need a "tach signal amplifier" to function properly.

Terminator Ignition Wiring with Holley HyperSpark Distributor

Here are the configuration settings you'll need to use when using the HyperSpark Distributor with your Terminator X (all software versions) or Terminator (using the Holley EFI version 5 or later software for the HP and Dominator ECU:)

- Ignition Type: Sniper HyperSpark TBI / 1 pulse per fire

- Ignition Reference Angle: 57.5 Degrees*

- Cam Sensor: Not Used

- Output Setup Type: Points Output

- Output Setup Dwell Time: 2.0 msec

*There are two errors that must be noted for Terminator X users. First, if you run the setup wizard on the Terminator X handheld and select the HyperSpark as your ignition choice, it is going to set the reference angle at 50 degrees--not 57.5. Of course, you'll catch that when you check your timing but if you don't realize that it is an incorrect IRA that caused this then you're going to adjust your distributor by 7.5 degrees and that is going to whack your rotor phasing. Fix your IRA, not your distributor. This problem persists at least through handheld firmware 1.0.8.

The second error is in the Terminator X software. If you go there and look at the ignition reference angle you're going to see that it is at 15 degrees. That is actually not the case. The control is errantly limited at 15 degrees so that is what it displays for anything over 15 degrees. Clearly, it is impossible to use this to set it at the correct angle of 57.5 degrees. Ignore the 15 degrees here and simply use your handheld to change your reference angle to 57.5 degrees. This problem persists through at least Terminator X software version V2.0 Build 50 and doesn't affect the standard HEFI HP/Dominator software used for the Terminator systems.

Here are the configuration settings you'll need to use when using the HyperSpark Distributor with your Terminator Ignition System using the Holley EFI version 4 software for the HP and Dominator ECU:

- Ignition Type: Custom

- Crank Sensor Type: 1 pulse/fire (Terminator V

- Crank Sensor Sensor Type: Digital Rising

- Crank Sensor Inductive Delay: 100.0 usec

- Crank Sensor Ignition Reference Angle: 57.5 Degrees

- Cam Sensor: Not Used

- Output Setup Type: Points Output

- Output Setup Dwell Time: 2.0 msec

Terminator Ignition Control Using Holley Dual-Sync Distributor

Terminator Ignition Wiring with Holley Dual Sync Distributor

Here are the configuration settings you'll need to use when using the Dual Sync Distributor with your Terminator Ignition System:

- Ignition Type: Custom

- Crank Sensor Type: 1 pulse/fire

- Crank Sensor Sensor Type: Digital Falling

- Crank Sensor Inductive Delay: 100.0 usec

- Crank Sensor Ignition Reference Angle: 50 Degrees*

- Cam Sensor Type: Single Pulse

- Cam Sensor Sensor Type: Digital Falling

- Output Setup Type: Points Output

- Output Setup Dwell Time: 2.0 msec

*Assuming you install your distributor with the engine timing a 50 degrees BTDC on the compression stroke as suggested.

Terminator Ignition Control Using GM Small Cap HEI Distributor

The EST/SPOUT signal is the same as is found in many factory ECUs. It is a +5V square wave trigger that is used to drive an HEI ignition module. Because of that, it can be used to control timing on a GM Small Cap HEI or Ford TFI distributor. This may work with other factory distributors that use an EST/SPOUT signal, but Holley only provides direct-fit adapter harnesses for these two at the time of this writing. The distributor produces a points output that sinks the current from the coil, initiating the spark at the timing determined by the ECU.

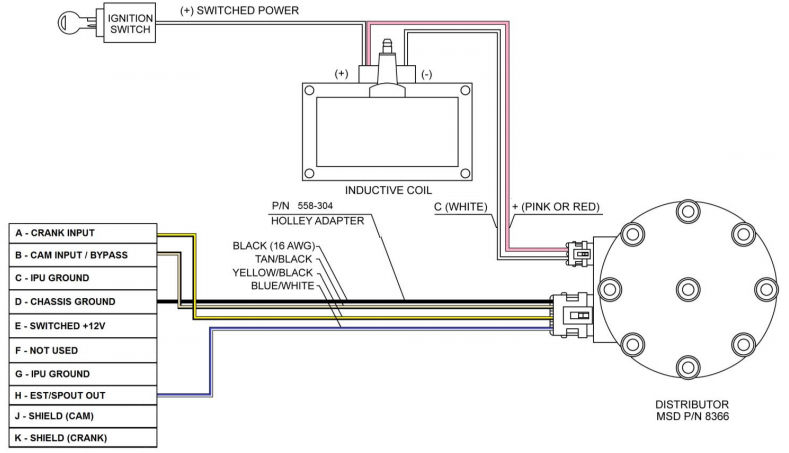

Terminator Ignition Wiring Without CD Box (GM Distributor Shown)

A couple notes about the diagram above. Shown is the GM small cap HEI distributor installation. See the Terminator instruction manual for Ford TFI example. Signals A-K represent the 10-pin ignition connector on the Terminator main harness. Note that while the adapter harness carries the cam signal from the distributor to the ignition connector on the Terminator main harness, Holley does not populate that pin with a wire back to the ECU.

If a capacitive discharge ignition box is used, then the points output generated by the electronically-controlled distributor will trigger the box to produce the spark ad the ECU-determined timing.

Terminator Ignition Wiring with CD Box (MSD 6A Shown)

Handy Ignition Check Tip (Ignitions Triggered with White Points Output)

Recognize that whenever the white points wire is grounded the ignition should throw a spark. Knowing that, you can follow these steps to do a quick sanity check on your ignition.

- Remove the coil wire at the distributor cap, insert a spark plug into the end and ground the spark plug securely to the engine..

- Turn the key to the "On" position but do not start or crank.

- Disconnect the 10-pin connector and momentarily ground the white points wire going to the ignition. Each time you do you should observe a spark on the cylinder identified above.

Conclusion

I hope that this article has helped to show that, once you understand some of the basics the different ignition configurations for the Holley Terminator and Sniper are not all that complicated. I would love to hear your comments or questions, so please post them below. I generally respond within one business day.

Click here to read more articles from Chris about the Sniper EFI System!

Posted by: kirstinkirstinmarquezea0252071.blogspot.com

Source: https://www.efisystempro.com/efi-pro-hangout/demystifying-holley-terminator-sniper-ignition-wiring